Atomic-level imaging of catalysts by scientists at the Department of Energy’s Oak Ridge National Laboratory could help manufacturers lower the cost and improve the performance of emission-free fuel cell technologies.

Fuel cells rely on costly platinum catalysts to enable the reactions that convert chemical energy into electricity. Alloying platinum with noble metals such as cobalt reduces the overall cost, but such alloyed catalysts vary in performance based on their atomic structure and processing history.

Tracking Platinum-Cobalt Nanoparticle Catalyst Reconfigurations with In Situ STEM

An Oak Ridge National Lab (ORNL) microscopy team used scanning transmission electron microscopy to track atomic reconfigurations in individual platinum-cobalt nanoparticle catalysts as the particles were heated inside the microscope. The in-situ measurements — acquired in real time in the vacuum of the microscope column with the use of the Protochips Atmosphere system — allowed the researchers to collect atomic level data that could not be obtained with conventional microscopy techniques.

“This is the first time individual nanoparticles have been tracked this way — to image the structural and compositional changes at the atomic level from the start of an annealing process to the finish,” ORNL coauthor Karren More said.

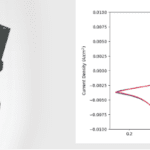

Very small changes in the positions of platinum and cobalt atoms affect the catalyst’s overall activity and selectivity, so annealing — a gradual heating, holding, and cooling process — is often used to modify the alloy’s surface structure. The ORNL in situ microscopy experiments documented exactly what, when and how specific atomic configurations originate and evolve during the annealing process.

“You can anneal something from room temperature to 800 degrees Celsius, but you don’t know at which point you should stop the process to ensure the best catalytic performance,” lead author Miaofang Chi said. “Because you don’t know how the particle evolves, you might be missing the optimum surface configuration.”

The atomic-level detail in the ORNL study will guide researchers and manufacturers who want to fine-tune their catalysts’ atomic structure to meet the demands of a specific application. “This work paves the way towards designing catalysts through post-synthesis annealing for optimized performance,” Chi said.

Research Specifications

The study is published as “Surface faceting and elemental diffusion behavior at atomic scale for alloy nanoparticles during in situ annealing” in Nature. Coauthors are ORNL’s Miaofang Chi, Karren More, Andrew Lupini and Lawrence Allard; Johns Hopkins University’s Chao Wang; University of Pittsburgh’s Yinkai Lei and Guofeng Wang; and Argonne National Laboratory’s Dongguo Li, Nenad Markovic, and Vojislav Stamenkovic.

The research was sponsored by the Fuel Cell Technologies Office in DOE’s Office of Energy Efficiency and Renewable Energy, and microscopy was performed at ORNL’s Center for Nanophase Materials Sciences, a DOE Office of Science User Facility.

Learn more about the applications and uses of catalysis in situ research.