In situ Transmission Electron Microscopy (TEM) has emerged as a powerful tool for studying dynamic processes unfolding at the nanoscale in real-time. From catalysis to material synthesis, or corrosion to biological materials, in situ TEM offers insights into the behavior of (nano)materials under various environmental conditions. However, the success of in situ TEM experiments critically depends on meticulous sample preparation. In this blog post, we show some advanced tools that are thoughtfully designed to help with sample preparation, increasing the reproducibility of results and a enabling a fast introduction into the TEM.

Understanding the Importance of Sample Preparation

Making your experiment successful all starts off with the preparation of a sample. In traditional TEM, the (powder) sample is usually suspended in liquid and then drop-casted onto a TEM grid. For in situ microscopy, there are several more steps to take into consideration depending on the in situ environment being utilized, whether it’s liquid with Poseidon AX, gas with Atmosphere AX, or heating/biasing in vacuum with Fusion AX. For example sample preparation for gas phase electron microscopy needs to be a lot cleaner then preparing samples using a heating or biasing holder. A small amount of dirt or dust can result into leaky experiments. On the other hand, having a good electrical contact using electrochemistry in liquid is of vital importance to scale your bulk experiments to the nanoscale. Lastly, to mimic battery materials in nanoscale, proper focus ion beam (FIB) preparation is really important.

Variety of Tools Available

Shadow Masking

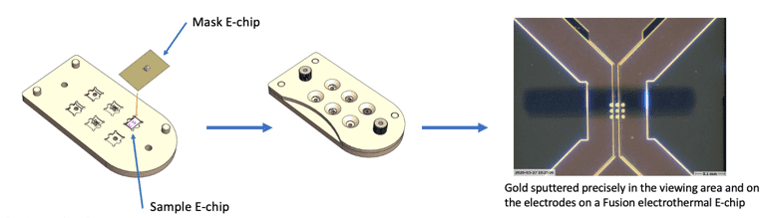

Shadow masking is a technique commonly used in various fields of microscopy, including electron microscopy, for precise patterning and deposition of materials onto substrates. Protochips offers a shadow mask that can help precisely deposit samples on the area of the E-chips that have the thin SiN windows in place. The shadow mask can be used in three different ways:

- Liquid dropcasting

- Powder (dry) deposition

- Sputter coating

The shadow mask offered by Protochips has three different slots for each of the variety of E-chips that are offered to support reproducible sample preparation from person to person.

If you are interested in the shadow mask and you would like to order it, find it in our shop!

FIB Lamella Deposition

Techniques such as focused ion beam (FIB) milling and ultramicrotomy are commonly employed to prepare thin sections of bulk materials suitable for in situ TEM observation, especially important for research surrounding batteries and corrosion of steels. The preparation of FIB lamella by itself already comes with many hardships, depending on the materials used. Protochips therefore offers a specialized FIB stub that helps with the nuanced process of transferring the FIB lamella to the surface of various E-chips.

Want to order this FIB stub for your research? Find it in our shop!

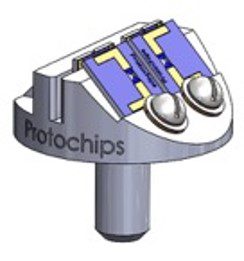

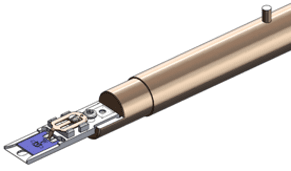

Inspection Holder

Once sample is deposited on the E-chip, assessing the deposition before beginning the in situ experiment is critical to ensure the deposition went as expected. The Protochips Inspection holder allows you to screen the sample deposition on the uniquely-shaped E-chips before going through the process of assembling and leak checking your Poseidon AX or Atmosphere AX holder. Depending on your interest to observe your sample in TEM or STEM mode, you have an option to inspect either large or small E-chip as the inspection holder comes with two tips that can hold either.

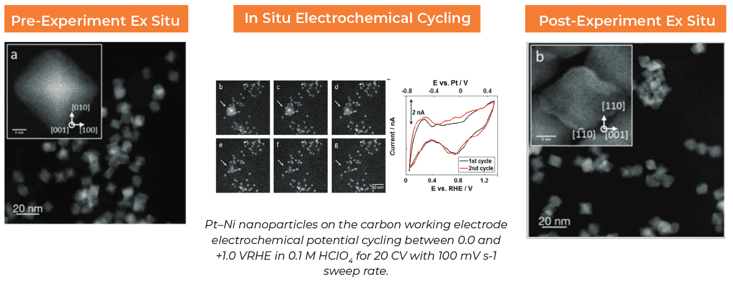

The screening stage of an experiment is also the ideal time to capture some high-resolution energy loss spectrometry (EELS) or energy-dispersive x-ray spectroscopy (EDS) of the pristine sample. Even though EELS, EDS and even 4D-STEM can be done in operando mode, it will always be useful to have a pre-experiment analysis step.

The screening stage of an experiment is also the ideal time to capture some high-resolution energy loss spectrometry (EELS) or energy-dispersive x-ray spectroscopy (EDS) of the pristine sample. Even though EELS, EDS and even 4D-STEM can be done in operando mode, it will always be useful to have a pre-experiment analysis step.

After the in situ experiment is complete, the inspection holder can then be used again to do identical location analysis at high resolution, higher than what may be achievable in situ, to complement the pre-experiment and in situ results.

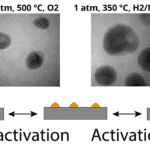

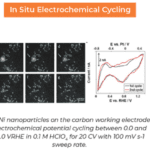

In the experiment below, researchers used liquid phase electrochemistry to observe Pt-Ni catalyst nanoparticles during cycling. They first observed their sample preparation on the large E-chip using the inspection holder before starting the experiments. During the reaction they observed changes on their nanoparticles using Poseidon AX with electrochemistry. Unfortunately, the electron dose can also interfere with experimental parameters in situ, therefore a final inspection was done post-experiment to see what the nanoparticles looked like in areas unexposed to the beam.

If you are interested in the inspection holder, please click here to email us!

Want to read more about this research? Find it here:

https://pubs.rsc.org/en/content/articlelanding/2019/ee/c9ee01185d