Liquid-phase transmission electron microscopy (LP-TEM) stands at the forefront of nanoscale imaging, offering a unique window into dynamic processes unfolding in liquid environments. With the increasing adoption of microfluidic reactors, researchers can precisely control the composition of sample solutions, opening avenues for studying various phenomena at the nanoscale. However, LP-TEM faces challenges concerning mass transport dynamics within the liquid cell and the reliable fixation of specimens for imaging.

The Need for Innovation

Conventional LP-TEM setups have a relatively small space available for liquid to be present. The introduction of flow in liquid cells has helped massively in changing out fluids to replenish active species in the cell, but still come with some limitations. One major issue in electrochemical experiments specifically, is the formation of gaseous products in the liquid cell. This limits the small systems to be used for relevant for energy applications as these gaseous products, resulting both from the reaction of interest and from water decomposition at the Working electrode (WE) and Counter electrode (CE), will slowly or quickly dry out the cells viewing area (window). This has called out for new innovations to be brought into existence to remove the gaseous species quickly and effectively from the window.

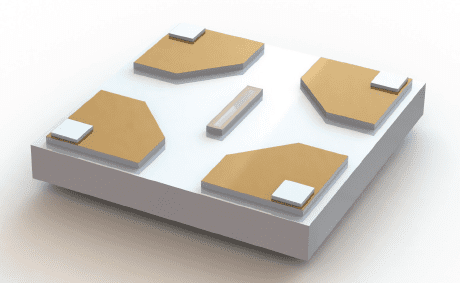

Flow Management Using E-chip Design

The flow management small E-chip design offers a breakthrough solution by integrating on-chip bypasses that enhance convective transport around the central nanochannel while maintaining predominant diffusive transport. Developed through rigorous numerical modeling and fabrication, diffusion cell prototypes demonstrate significant improvements over existing setups.

The new E-chips offer:

- Swift removal of unwanted gas bubbles to prevent ending an experiment prematurely

- Controlled creation and removal of bubbles, if desired, for trying to increase imaging resolution

- Extended electrical potential ranges due to increased amounts of liquid in the right areas

- Best compromise between bulk-like and nanoscale environments, with larger amounts of liquid around the reference and counter electrodes, but thin layers of liquid in the imaging area

- Pair with our new thinner-spacer (100 nm) electrochemistry E-chips for the highest success rates with the thinnest liquid layers.

Enhanced Hydrodynamic Parameters

Enhanced Hydrodynamic Parameters

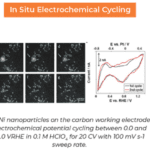

These new E-chips not only remove bubbles formed either at the WE or the CE effectively, they additionally improve the hydrodynamic parameters by 2-3 orders of magnitude compared to traditional configurations. These improvements translate into rapid solution replacement dynamics, matching or even surpassing the mixing timescales observed in many ex-situ scenarios. The flow management E-chips integrate into existing LP-TEM workflows, offering researchers enhanced correlation capabilities with ex-situ experiments. Moreover, they pave the way for exploring new research directions by enabling the study of fast nanoscale processes previously inaccessible with conventional setups.

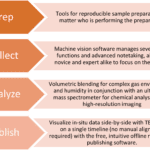

Workflow for Success

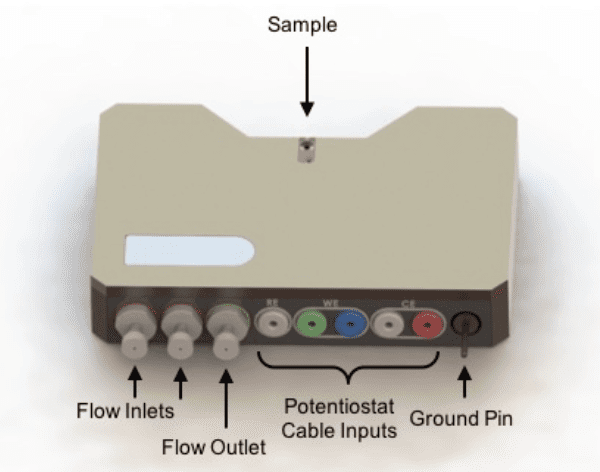

Using these newest developments, Protochips aims to create a workflow to scale bulk electrochemistry to nanoscale processes. This always starts off with sample preparation. The E-chip selection is an important part of these, where we offer >200 combinations of E-chips tailored for each experiment. Once an E-chip combination has been chosen, the sample will be prepared using any of our preparation tools, such as the shadow mask or FIB stub (for battery studies). The sample can then be inspected in an ex situ check, using the inspection holder, which can also be used for pre-experimental high resolution EELS/EDS and 4D-STEM. To scale down the electrochemical processes, first tests can be done on the benchtop using the ex-situ cell.

This is an exact replica of the holder tip (same gaskets and E-chips) which helps validate that the experiment occurring in the cell is comparable to what you are familiar with on the benchtop. From here on it is time to work with the holder in the microscope and observe true in situ electrochemical experiments happening in real time and at the nanoscale. An additional tool to validate the experiments and compare them to bulk experiments, is to use a standard reference electrode with the holder. Finally the inspection holder can be used once more for post-mortum analysis.

Want to order these E-chips? Find them here!

Want to know more about how to do in situ electrochemical research? Download the one pager here!

Want to know more about in situ liquid phase electron microscopy? Download the brochure here!

Read more about the research done to support the innovation of these E-chips here: