Over the past several years, the use of in situ gas phase electron microscopy to study the behavior of catalysts in real time under relevant atmospheric conditions has increased significantly. Since catalyst performance is based on atomic and nanoscale properties, observing changes of nanoscale phenomena can help researchers understand the causes for large scale changes in material stability, activity, or selectivity. However, observing nanoparticle behavior without understanding the gas composition leaves a large knowledge gap in the lifecycle of catalysts. The integration of residual gas analyzer (RGA) technology into the Protochips’ Atmosphere AX system fills this knowledge gap and enables you to study catalyst structure as it relates to its function. The main challenges with integrating a mass spectrometer are:

Over the past several years, the use of in situ gas phase electron microscopy to study the behavior of catalysts in real time under relevant atmospheric conditions has increased significantly. Since catalyst performance is based on atomic and nanoscale properties, observing changes of nanoscale phenomena can help researchers understand the causes for large scale changes in material stability, activity, or selectivity. However, observing nanoparticle behavior without understanding the gas composition leaves a large knowledge gap in the lifecycle of catalysts. The integration of residual gas analyzer (RGA) technology into the Protochips’ Atmosphere AX system fills this knowledge gap and enables you to study catalyst structure as it relates to its function. The main challenges with integrating a mass spectrometer are:

- Vibrations – RGAs require rough pumps to support their vacuum environment which causes a loss in spatial resolution from vibration.

- Response time – quick response times support easier alignment of TEM images and RGA data and prevents peak broadening, however moving it closer to the TEM affects the resolution.

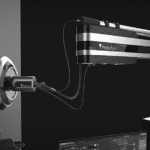

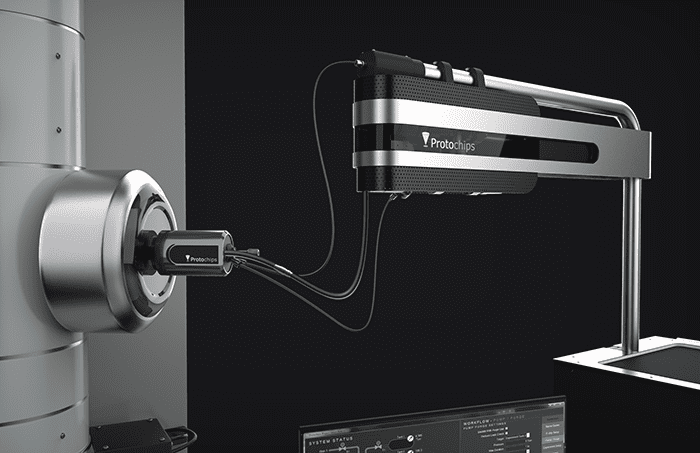

Protochips has taken these two main challenges into account with the design of our integrated RGA, making it the first RGA designed specifically to be used alongside a TEM:

- Image at high resolution while the RGA is operation – the unique design of the Atmosphere AX’s manifold system has allowed the integration of the RGA into the vacuum design and enables operation of the RGA with the need of a noisy roughing pump.

- Maximized response times – the integration of the system allowed mounting on the Atmosphere AX’s boom and gets it as close as 0.5 m from the TEM without affecting imaging resolution. Initial response times are as fast as 3 seconds or better, maximizing signal to noise for these nanoscale reactions.

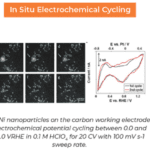

RGA measurement of products normalized to the CO gas measurements. The composition of the support structures (SiO2 top Al2O3 bottom) impact both the onset of activation and selectivity.

For example, one study looked into the behavior of catalysts that can convert syngas (CO/H2) into olefins and paraffins for fuel production. The authors used cobalt/platinum catalysts at industrially relevant temperatures and pressures (430 °C, and 105 Pa) and combined this with RGA analysis. This resulted in insights into the relative performance and lifetime of cobalt/platinum catalysts. By combining high-resolution TEM with RGA data, researchers gain crucial insights into catalyst performance, enabling accurate interpretation of active-state behavior.

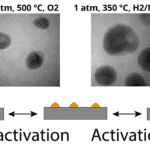

In situ HAADF-STEM images of Co/Pt catalysts supported on SiO2 (top) Al2O3 (bottom), before (left) and after (right) exposure to first H2 (430 °C, 101.3 kPa) and later under syngas (H2/CO = 2,220 °C, 101.3 kPa).

The Atmosphere AX system was designed to support your research by giving you the best opportunity to obtain structural information that can be aligned with the gas product information for a complete understanding of your catalyst’s performance.

Want to learn more about our machine vision-based Atmosphere system? Download our brochure here!

If you want to know more about how Atmosphere AX can be used for catalysis research, download the one pager here