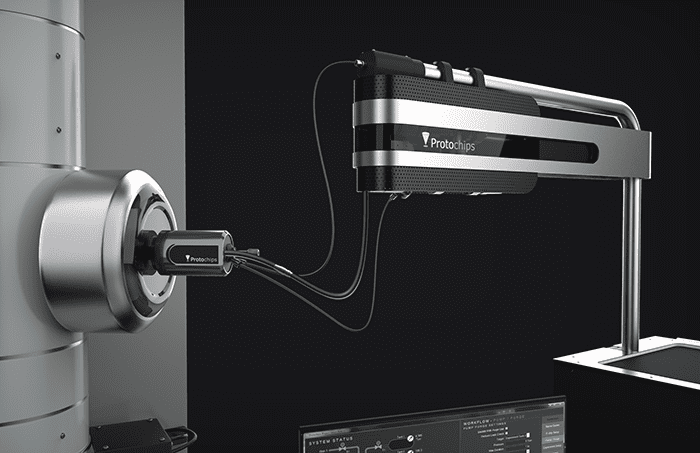

Protochips’ new integrated residual gas analyzer (RGA) brings you closer than ever before to nanoscale operando experiments.

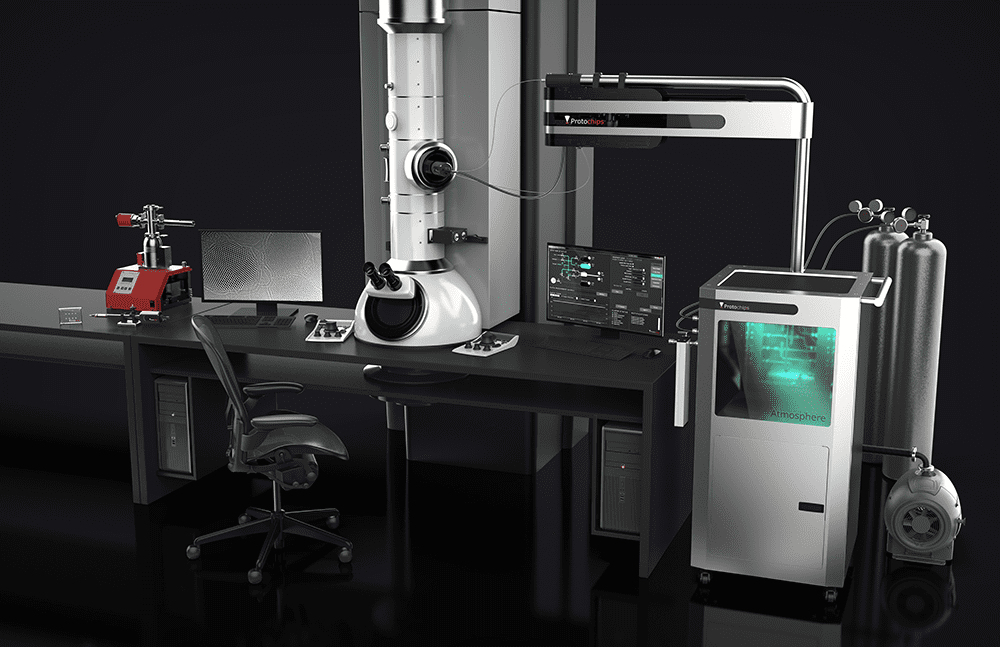

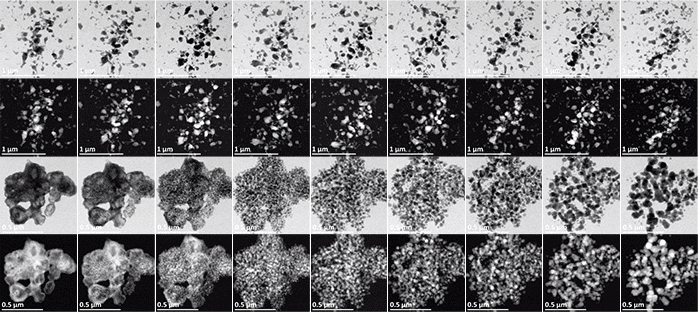

Realistic Operating Environments

Accurately blend and flow custom gas mixtures to re-create even the most complex catalyst operating environments. Utilize anything from a single component gas to a custom industrial exhaust and add up to 1000ºC of heat.

Integrated Gas Analysis

Integration of the RGA enables superior image stability and rapid gas detection during your experiments. Software-controlled cleanliness checks ensure safe exposure of the gas manifold to the RGA for residual gas inspection prior to and in between experiments.

Controllable Vapor Introduction

Software-controlled introduction of water and solvent vapors enables a level of precision and reproducibility otherwise unattainable. Introduce humidity, alcohols, light alkanes, and other sources as pure vapors or mix them with a carrier gas while preventing condensation.

Want to speak to a product specialist or get a quote? Let us know what we can help you with so we can continue this conversation in more detail.