Over the past several years, attention has increasingly focused on engineering catalysts at the nanometer scale to simultaneously increase catalyst activity and decrease the amount of expensive precious metals required. These efforts have generated a number of new successful catalysts, however, significant hurdles remain before widespread adoption of nanoparticle catalysts occurs.

A New Catalyst System for Methane Combustion

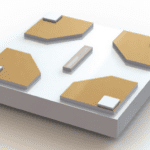

Recently, Cargnello, et al., reported on a new catalyst system with exceptional activity for methane combustion in Nature. The catalyst consists of a modular palladium–ceria core–shell subunits on silicon-functionalized alumina. The idea of the core-shell structure is to protect the small palladium nanoparticles from sintering at elevated temperatures, which can reduce activity, while maintaining access to the palladium surface.

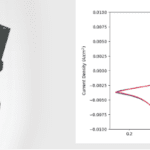

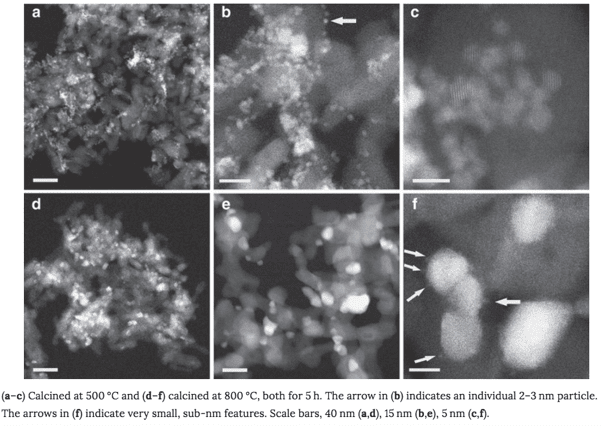

Researchers at University of Michigan set out to understand the catalyst behavior using advanced electron microscopy techniques, including in situ transmission electron microscopy (TEM), capable of atomic resolution analysis. They showed that the modular palladium–ceria core–shell subunits undergo structural evolution over a wide temperature range. In situ, real-time observations performed in the TEM using the Atmosphere gas cell system provided direct evidence that the palladium-ceria core-shell subunits participate in a dynamical process that leads to the formation of a mixture of palladium, cerium, silicon and oxygen, with very high dispersion, and a coarse mixture of ceria and palladium particles.

The presence of these two distinct forms was unexpected, and occurs upon air calcination at temperatures between 500 and 800 °C. This result was confirmed using both ex-situ and in-situ experiments. The researchers suggest this newly observed, highly dispersed structure is the source of the exceptional catalyst activity, and warrants additional investigations.

“Without in-situ observation, the dynamic structural evolution is unlikely to be envisioned by any ex-situ method and more importantly, this finding may open new perspectives about the origin of the activity of this catalyst,” said Shuyi Zhang, first author of the article.

Research Specifications

All experiments were carried out in a JEOL JEM-2100F in scanning TEM mode (Cs probe correction) operated at 200 kV. The Protochips Atmosphere system consists of a MEMS-based closed cell holder, fully automated gas manifold and workflow based control software capable of achieving temperatures up to 1000C and pressures of 1 Atm.

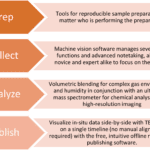

Learn more about Atmosphere’s capabilities to support in situ catalyst research applications.